Eagle Stars brand Futamura Machines & Tools Co., Ltd.

As a specialized manufacturer of Rolling centers,

we are committed to meeting our customers’ needs.

What Is a Rolling Centers?

What Is a Rolling Centers?

A tool for supporting long workpieces, equipped with a rotating tip.

A rotating holder that supports the workpiece center during machining to prevent runout and deflection.

A rolling center has a 60° conical tip and a tapered shank for accurate workpiece support.

At FUTAMURA MACHINES & TOOLS, we call it a “Rolling Center.”

What Is a Work Driving Centers?

Mounted on the spindle side opposite the Rolling Center, it supports the workpiece at the end face in place of a chuck and is used between centers.

By holding the workpiece at its end face, no chuck allowance is needed, and flipping is unnecessary. This improves accuracy, reduces machining time, and saves material. However, the current model is not suitable for hardened workpieces.

At FUTAMURA MACHINES & TOOLS, it is called a “Work Driving Center,” while other manufacturers refer to it as a Face Driver.

Maintenance Recommendations

Rolling Centers are consumable tools. With regular maintenance, they can last much longer.

If you notice abnormal rotation, unusual noise, or tip damage, please consult FUTAMURA MACHINES & TOOLS.

For further information, please consult FUTAMURA MACHINES & TOOLS.

-

about Rolling Centers

-

Can we use your products for grinding machines?

The high-precision NC70 and NCF models with (optional) V seal specs can be used.

-

Can we process a workpiece even with a shank other than Morse Taper shanks?

You can do so with a straight shank or any other taper shanks, if you have a gauge. We may ask you to provide a gauge.

-

Should we replenish grease for the bearing part?

We measure grease and apply it at the time of assembly. Accordingly, you do not need to replenish grease. If grease is applied too much, it will generate heat.

-

Is the bearing part of the body heated?

Heat is generated by the rotation of the bearing. The highest temperature in the normal temperature range is room temperature plus 50 degrees Celsius.

-

Can we process a workpiece at a tip angle other than 60, 75 and 90 degrees

You can do so. However, you need to provide a gauge, etc. in some cases.

-

What is the tolerance of a tip angle of 60 degrees?

It is 0 to 30 minutes.

-

Have you measured the precision of the outer diameter of the center shaft?

For precision measurement, we measure the center runout at the conical part of the center shaft. In some cases, the precision of the outer diameter of the

center shaft has not been measured. -

Is it possible to use a high-pressure coolant for a product with a seal?

Our products are not totally waterproof. Coolant would enter the bearing part, causing corrosion. Please avoid it.

-

What is the hole of the model 100 with a seal?

That hole is for draining water. When setting a rolling center, please be careful so that the hole faces downward.

-

Is it possible to produce a product whose tip can be replaced?

We can produce it with special specs.

-

-

about Work-Driving Centers

-

Can we use the work-driving center for a workpiece that has been sintered or well-tempered?

You cannot do so, because jaws do not grip a workpiece that has been hardened through sintering or the like.

-

Can we use it for a grinding machine?

You cannot do so, because jaws do not grip a workpiece that has been hardened through sintering. In addition, there are problems with the processing

precision and the pressing force of the tailstock. -

Is the center hole necessary?

It is necessary because the processing is conducted with two centers.

-

Is a center shaft available?

It is not available, because respective center shafts and centers are gauging after production.

-

-

about Bevel Rolling Centers

-

Do you produce a specially shaped product?

Please specify specs, including small diameter, large diameter, angle and shank (Morse Taper).

-

Is it possible to conduct detachment with a removal nut mounted on the tailstock?

BRF types are all compatible with a tailstock with a detaching nut. For the Morse taper size not listed in the catalogue, please contact us.

-

-

about Lathe Centers

-

Do you produce a lathe center without a carbide tip?

We can receive orders for specially shaped products. Please specify dimension and specs, and contact us.

-

If a carbide tip is damaged or removed, is it possible to braze a new one?

No. It would cause distortion and lose precision.

-

-

about information/other

-

Do you repair other makers’ products?

No, we don’t, because the specs of parts and tools are different.

-

Do you repair any kinds of your products?

Some models cannot be repaired. Please contact us.

-

Do you dispose of products that cannot be repaired?

If you request, we will dispose of them.

-

Do you supply parts, etc.?

We do not sell parts of products. We will deal with your troubles through repair.

-

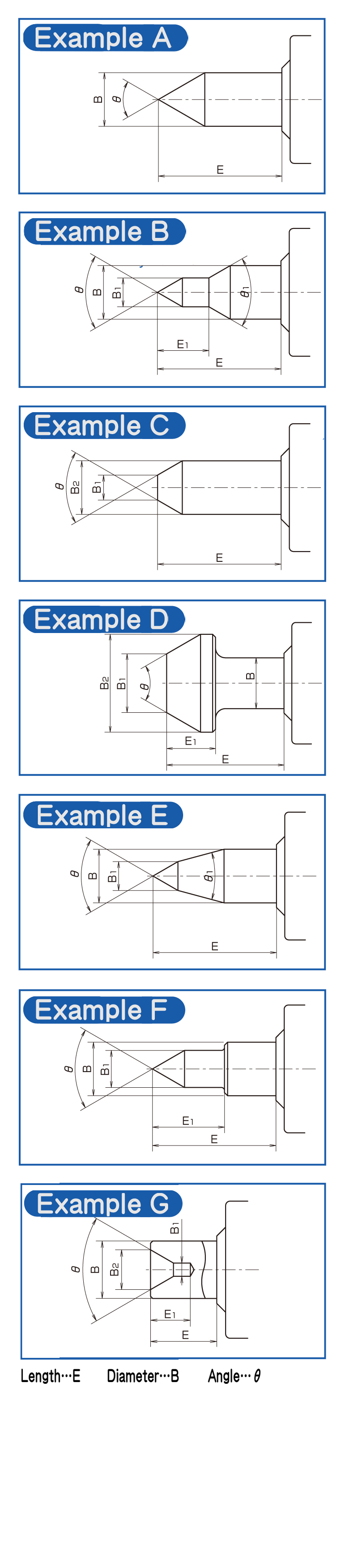

We manufacture special-shape centers suitable for machines and workpieces.

Select from the special shape examples below and fill in the blanks with the dimensions required.

Order example : Example A N0.4 B=26 B1=10 B2=26 E=60 θ=60°

Clicking the Send button sends an email to  .

.

When we receive the email, our staff will contact you.

contact information

-

Headquarters/

Nagoya OfficeTEL.+81-52-411-1196

FAX.+81-52-412-8882

E-mail.

-

Tokyo Office

TEL.+81-3-5741-3821

FAX.+81-3-5741-3841

E-mail.

-

Osaka Office

TEL.+81-6-6448-0401

FAX.+81-6-6448-0404

E-mail.

-

Shizuoka Office

TEL.+81-54-643-1196

FAX.+81-54-643-9772

E-mail.

We at Futamura Machines & Tools Co., Ltd. are aware that our mission is to pursue advanced technology even deeper and deliver superior products, and we hope to be a company that is trusted because of our reliable technology.

Users’ needs are becoming increasingly sophisticated today and will continue in the future. In response to this, the industrial machinery of machine manufacturers is becoming more sophisticated and value-added, and, in particular, processing accuracy is now required at the submicron level. Since its foundation in 1946, Futamura Machines & Tools Co., Ltd. has consistently been involved in the development and manufacture of precision machine tools.

Making full use of the know-how we have accumulated over the years, we have also made efforts to develop new technologies and have acquired numerous industrial property rights, including a number of patents, which evolved into our Eagle-branded high-precision products. Thanks to your support, our products with outstanding excellence are recognized as meeting users’ exacting expectations, and we are very much trusted by many major and first-class users; we believe that we play a fundamental role in each industry.

All of our employees are making efforts, filled with motivation. We really appreciate your continued support and feedback.

President Tadahiro Futamura

-

Company Name

Futamura Machines & Tools Co., Ltd.

-

Establishment

September 1948

-

Address

55 Kutanjo, Iwatsukacho, Nakamura-ku Nagoya-shi, Aichi, Japan

-

President

Tadahiro Futamura

-

Number of Employees

52 employees

-

Business Description

Manufacturing and sales of precision machine tools

-

Main Products

”Eagle Stars” Brand

Rolling centers

Work-driving centers

Bevel Rolling centers

Additional precision machinery and tools

-

Principal Banks

MUFG Bank,

Otobashi Branch

Bank of Nagoya,

Iwatsuka Branch

Juroku Bank,

Nakagawa Branch

-

Headquarters

Factory

Nagoya Office

453-0862

55 Kyutanjyo, Iwatsuka-cho, Nakamura-ku, Nagoya-shi, Aichi, Japan

Tel: +81-52-411-1196 (Main line)

Fax: +81-52-412-8882

-

Osaka Office

553-0003

4-2-76 Fukushima, Fukushima-ku, Osaka-shi, Osaka, Japan

Tel: +81-6-6448-0401 (Main line)

Fax: +81-6-6448-0404

-

Tokyo Office

146-0083

3-20-4 Chidori, Ota-ku, Tokyo, Japan

Tel: +81-3-5741-3821(Main line)

Fax: +81-3-57413841

-

Shizuoka Office

426-0036

177-3 Kamiaojima, Fujieda-shi, Shizuoka, Japan

Tel: +81-54-643-1196 (Main line)

Fax: +81-54-643-9772

-

Tsushima Factory

496-0008

107 Kohunato, Uji-cho, Tsushima-shi, Aichi, Japan

-

March 1946

Tadao Futamura personally founded Futamura Manufacturing.

-

September 1948

Reorganized as a corporation and became Futamura M&T Co., Ltd.

-

September 1948

Opened the Osaka Sales Office in Osaka.

-

April 1960

Expanded the factory.

-

March 1968

Established a second factory and a new office.

-

February 1970

Opened the Tokyo Sales Office in Tokyo.

-

November 1975

Received an award from the Governor of Aichi Prefecture.

-

December 1985

Completed new head office building.

-

November 1988

Commended as an excellent tax-reporting corporation.

-

November 1992

Tadao Futamura received the Order of the Sacred Treasure, Gold and Silver Rays.

-

February 1993

Tadanori Futamura was appointed President and Representative Director.

-

December 1997

Established a new East Factory at the headquarters.

-

August 2009

Established new West and North Factories at the headquarters.

-

September 2012

Tadahiro Futamura was appointed President and Representative Director.

-

March 2017

Recognized as an Aichi Quality Company.

-

February 2021

Established the Tsushima Factory.

-

November 2021

Opened the Shizuoka Sales Office in Fujieda City, Shizuoka Prefecture.

-

December 2021

Recognized among METI's "300 Vibrant SMEs

-

September 2023

Certified as an Aichi Prefecture Work-Life Balance Reform Master Company

-

NC Lathes

7 units

-

Various Types of Lathes

7 units

-

CNC Grinding Machine

2 units

-

Microcomputer-controlled Internal Grinder

6 units

-

Various Types of Grinding Machines

14 units

-

Various Types of Milling Machines

3 units

-

Various Types of Drilling Machines

6 units

-

Other Types of Machines

3 units

-

Various Types of Jigs and Tools

Complete set

-

List of Inspection Equipment

Roundness Measuring Instrument

Surface Roughness Measuring Instrument

Rotational Testing Machine

Coordinate Measuring Machine, etc.